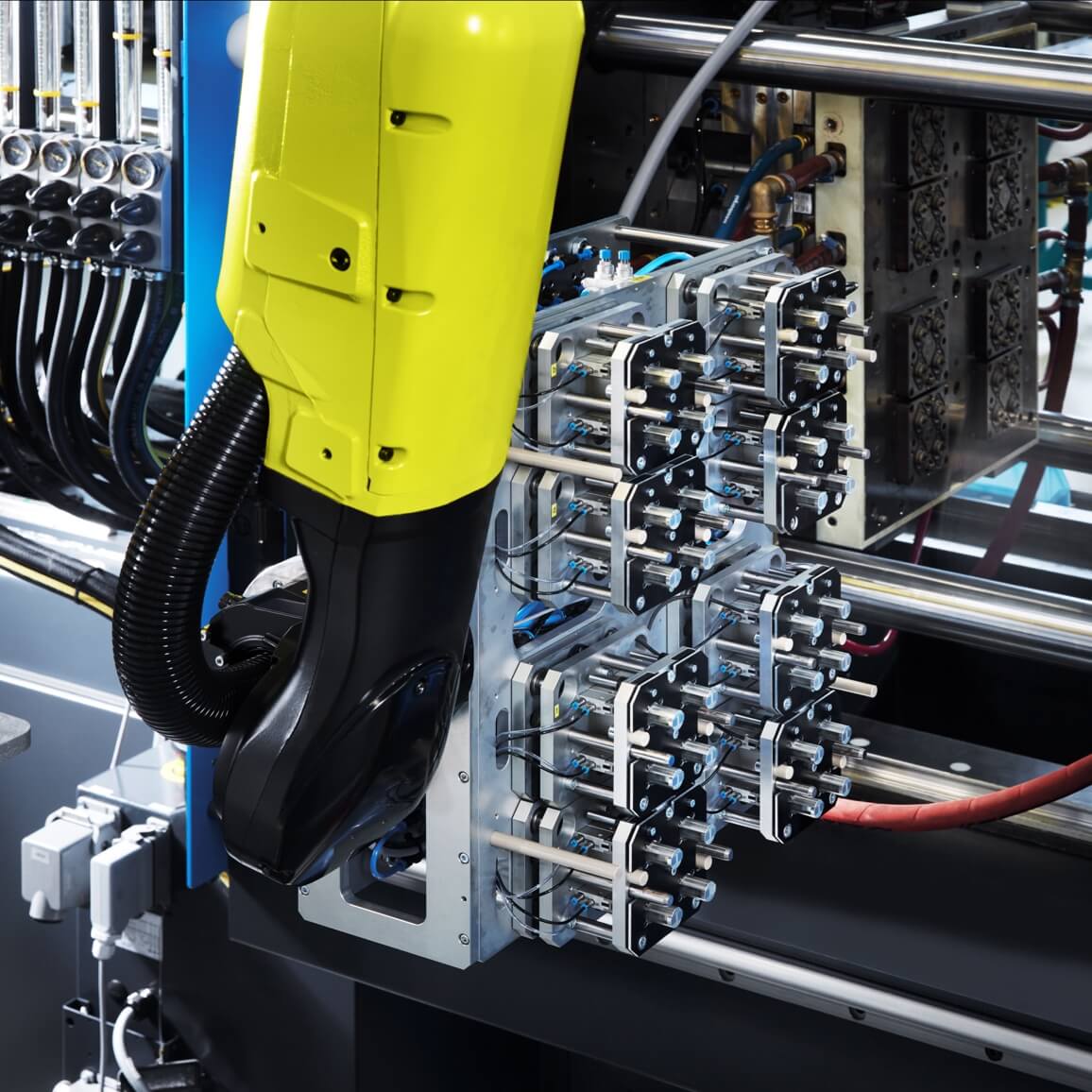

Optimal operation thanks to optimal conditions

In close cooperation with the customer, a Nexus HTV cold runner with Flowset Electric balancing system was added, which reduced the injection pressure enormously. The controllability of the flow can now be regulated and optimized in each cavity. Cleaning time and the amount of deposited material in the cold runner have also been cut in half thanks to the new Nexus solution. Short communication paths and in-depth experience with different types of material make Nexus a highly qualified partner.